_

Products

We are producing parts for various machines and products and deliver to multiple branches. More than 70.000 electric heaters are daily produced in our plants. Surely, you meet us all the time.

_

Stock Program

Stock Program

High performance cartridge heater Type HLP

DESCRIPTION

Metal-sheathed cartridge heater with ground sheath. The special construction allows an extremely high surface loading, i.e. maximum power in the smallest possible space. UL-approved executions available

TECHNICAL DATA

| Possible voltages | to 1000 V |

| Surfce loading | approx 3-50 W/cm² |

| Temperature | approx 750°C max. |

| Operating diameter (mm) | up to 2,8 mm - 32 mm |

| Operating diameter (inch) | from 1/8 |

| Connections | Solid wire or flexible leads. Custom-made lengths. |

APPLICATION

Plastics industry, apparatus construction, woodworking industry, paper machine industry, medical technology, foundries, high vacuum technology, laboratory work, packaging industry.

Contact Persons

Jürgen Wiggenhauser

Technical Sales

HP – Nozzle heaters

HLP – High performance cartridge heaters

HLPR – PTC-heating elements

Fax: +49 (0) 74 61-70 14 - 148

Email: wiggenhauser@tuerk-hillinger.de

Lucas Denger

Order Processing

HLP – High performance cartridge heaters

PMV – Compacted heating element

Emily Hermes

Order Processing

HLP – High performance cartridge heaters

PMV – Compacted heating element

Wanesa Jovanovic

Order Processing

HLP – High performance cartridge heaters

Kristina Bluhm

Order Processing

HLP – High performance cartridge heaters

ALW – Braking/Retardation resistors

Automotive high-power cartridge heater Type HLPA

DESCRIPTION

High power cartridge heater for thermostats or preheating of oil or petrol. High compactness allows high surface loading, i. e. giving the maximum power in the smallest space.

TECHNICAL DATA

The HLPA low-resistance heating elements are well-known for their vibration resistance, high surface quality, fast response and pressure resistance. Upon request, we can supply specialty heaters with connectors or other coupling elements.

The HLPA type cartridge heaters can be manufactured according to specific requests of the customer.

APPLICATION

Automotive industry

Contact Persons

Christoph Fodor

Sales Manager

Christoph Fodor

Sales Manager

HLPA – Automotive high-performance heating cartridges

RKW – Electric railway switch heaters

RP – High performance tubular heaters

SCHUWI – Protective resistors

TE – Temperature sensors

High Performance cartridge heater Type RP

DESCRIPTION

High performance tubular cartridge heaters offer a high watt density at a low mass. They are used, where space is at a premium. RP/RPT type heaters are available with and without thermocouple.

TECHNICAL DATA

| Possible voltages | 24 V up to 250 V |

| Power | max 80 W/100 mm length |

| Temperature resistance | up to max. 750°C |

| Possible cross-sections | up 1,2 mm to 9,0 mm |

APPLICATION

In the plastics industry for the heating of nozzles and hotrunner systems. Generally applied where space is restricted.

Contact Persons

Lisa Eistetter

Order Processing

HP/T – Nozzle heaters

HPQ – Nozzle heater Q-series

RP – High performance tubular heaters

TE – Temperature sensors

Fax: +49 (0) 74 61-70 14 - 155

Email: lisa.eistetter@tuerk-hillinger.de

Carmen Jurj

Order Processing

PMVA – Compacted heating cartridges

RKW – Electric railway switch heaters

RP – High performance tubular heaters

SCHUWI – Protective resistors

TE – Temperature sensors

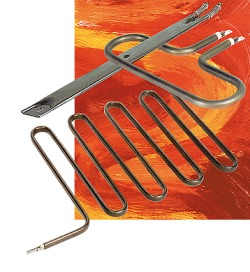

Flat tubular heater Type RKF

DESCRIPTION

Compacted and metalsheathed heater with flat oval crossection; one-, two- or three- connection pins on one or both sides.

Sheath material: CrNi-steel. Heat conductor: Chrome nickel wire NiCr 8020 or other NiCr alloys. Insulation material: Pure magnesium oxide

TECHNICAL DATA

| Max. voltage | 480 V |

| Max. temperature load of sheath | 700°C |

| Cross-section | 13 x 5,5 mm / 17 x 6 mm / 22 x 6 mm |

| Max. length | about 5000 mm |

APPLICATION

Air and gas heaters, fluid heaters, oil heaters, dryers, heating element for railway points.

Contact Persons

Ralf Kuppel

Technical Sales

FLC – Flat heating elements

ALW – Braking/Retardation resistors

RKF – Flat tubular heaters

Diane Fiedler

Order Processing

EHK – Immersion heaters

FLC – Flat heating elements

RKF – Flat tubular heaters

FLEX – Flexible tubular heater

Nozzle heater Q-series Type HPQ

DESCRIPTION

The nozzle heaters type HPQ are a further development of the conventional Türk+Hillinger nozzle heaters type HP. Basis of the nozzle heaters type HPQ is a low mass tubular heater type RP/RPZ, coiled into a slot of a cylindrical sleeve with precise ID. Optional the nozzle heaters are deliverable with or without thermocouple.

Advantage

- precise power distribution

- customer specific designs

- highest reproductivity

- smallest tolerances

- compact and robust design with small wall thickness

TECHNICAL DATA

| Base material | Brass or CrNi tube Sheath material of the tubular cartridge heater Nickel or CrNi-steel |

| Inner diameter | 5 - 30 mm (tolerance + 0,03) |

| Length | 20 - 400 mm |

| Min. wall thickness | 1,3 mm |

| Voltage | 12 - 230 V |

| Power tolerances | + - 10 % (smaller on request) |

| Power distribution | upon customer specification |

| Connection type | upon customer specification |

| Optional | available with integrated thermocouple |

APPLICATION

Heating of nozzles for the plastics industry, e.g. hotrunner systems, heating of liquids within tubes, heating of metals with circular cross section.

Contact Persons

Lisa Eistetter

Order Processing

HP/T – Nozzle heaters

HPQ – Hohlpatrone Q-Serie

RP – High performance tubular heaters

TE – Thermocouple

Fax: +49 (0) 74 61-70 14 - 155

Email: lisa.eistetter@tuerk-hillinger.de

Ralf Huber

Deputy Sales Manager

HPQ – Nozzle heater Q-series

Fax: +49 (0) 74 61 - 70 14 - 148

E-Mail: huber@tuerk-hillinger.de

Nunzio Pastore

Technical Sales

FLEX – Flexibler Rohheizkorper

Fax: +49 (0) 74 61 70 14 - 97 237

E-Mail: npastore@tuerk-hillinger.de

Nozzle heater Type HP

DESCRIPTION

The heater consists of a low mass tubular cartridge heater type RP or RPT coiled into a cylinrical sleeve with precise ID. It is available with or without thermocouple

TECHNICAL DATA

| Voltages | up to 230 V |

| Current max. | 4 A |

| Watt density | max. 15 W/cm² |

| Dielectric strength | 1000 V |

| Max. temperature on inner tube | 450°C with a brass-inner sleeve 700°C with a CrNi-steel-inner sleeve |

APPLICATION

Heating of nozzles for the plastics industry, heating of liquids within tubes, heating of metals with circular cross section.

Contact Persons

Jürgen Wiggenhauser

Technical Sales

HLP – High performance cartridge heaters

HLPR – PTC-heating elements

Fax: +49 (0) 74 61-70 14 - 148

Email: wiggenhauser@tuerk-hillinger.de

Lisa Eistetter

Order Processing

HP/T – Nozzle heaters

HPQ – Nozzle heater Q-series

RP – High performance tubular heaters

TE – Thermocouple

Fax: +49 (0) 74 61-70 14 - 155

Email: lisa.eistetter@tuerk-hillinger.de

Tubular heater Type RHK

DESCRIPTION

Metal-sheathed compacted tubular heater, available in straight or bent execution. Threaded stud connections i. e. at both ends.

TECHNICAL DATA

| Max. voltage | 480 V |

| Sheath material | Cu und CrNi-Stahl |

| Diameter | 16 mm, 8,5 mm, 6,5 mm, 5 mm, 4 mm, 3 mm |

| Max. length | Ø 16 mm und 5 mm ca. 3000 mm Ø 8,5 mm ca. 4000 mm Ø 6,5 mm ca. 3800 mm Ø 4 mm und 3 mm ca. 1500 mm |

APPLICATION

Air and gas heaters, fluid heaters, oil heaters, dryers, heating element for railway points.

Contact Persons

Diane Fiedler

Order Processing

EHK – Immersion heaters

FLC – Flat heating elements

RKF – Flat tubular heaters

FLEX – Flexible tubular heater

Flexible tubular heater type FLEX

DESCRIPTION

The FLEX is a robust tubular heating element with excellent thermal properties, which can freely be bent by hand. Each heater must undergo an individual test i.a.w. (VDE 0700).

TECHNICAL DATA

| Sheath material | Stainless steel |

| Heat element sheath temperature | 700°C |

| Standard connection voltage | 230 V |

| Dielectric strength* | 1.000 V AC |

| Insulation resistance* | ≥ 5 MΩ at 500 V DC |

| Leakage current* | < 0,5 mA at 253 V AC |

| Power tolerance | +/- 10% |

| Length tolerance | +/- 3,0% |

| * tested at room temperature |

APPLICATION

For heating up hot runner systems in the plastic industry and other industrial application.

Contact Persons

Diane Fiedler

Order Processing

EHK – Immersion heaters

FLC – Flat heating elements

RKF – Flat tubular heaters

FLEX – Flexible tubular heater

Nunzio Pastore

Technical Sales

FLEX – Flexible tubular heater

Fax: +49 (0) 74 61 70 14 - 97 237

E-Mail: npastore@tuerk-hillinger.de

Temperature sensors Type TE

DESCRIPTION

The sheathed thermocouple type TE consists of a thermocouple which is integrated in a stainless steel shealth and embedded in highly compacted magnesium oxide for an optimum electrical insulation. Easy to bend.

TECHNICAL DATA

| Shealth material | CrNi-steel AISI 321 |

| Insulation | highly compacted magnesium oxide |

| Max. temperature | Fe-CuNi 600°C, NiCr-Ni 750°C |

| Insulation resistance | > 50 MOhms |

| Diameter | 1,0 and 1,5mm |

APPLICATION

Temperature measuring in heaters, especially injection nozzles for the plastics industry.

Contact Persons

Lisa Eistetter

Order Processing

HP/T – Nozzle heaters

HPQ – Nozzle heater Q-series

RP – High performance tubular heaters

TE – Temperature sensors

Fax: +49 (0) 74 61-70 14 - 155

Email: lisa.eistetter@tuerk-hillinger.de

Carmen Jurj

Order Processing

PMVA – Compacted heating cartridges

RKW – Electric railway switch heaters

RP – High performance tubular heaters

SCHUWI – Protective resistors

TE – Temperature sensors

Power resistor Type ALW

DESCRIPTION

Compacted resistor with flat rectangular section. Applications include the smoothing of power peaks for electronic speed controllers.

TECHNICAL DATA

| Tensions | up to 800 V |

| Sheat temperature | max 250° C |

| Temperature controller | 130° C |

| Section | 40 x 20 mm or 80 x 20 mm |

| Length | 160 mm, 240 mm, and 300 mm |

| Range | from 1 - 500 Ohms |

| Dielectric strength | 4000 V |

| Connections | PTFE-insulated copper leads |

APPLICATION

Frequency transformer, manufacturing industry, electrical industry, apparatus construction, inverters, speed controllers.

Contact Persons

Ralf Kuppel

Technical Sales

FLC – Flat heating elements

ALW – Power resistor

RKF – Flat tubular heaters

Kristina Bluhm

Order Processing

ALW – Power resistor

Steel grid element resistors Type EPH

DESCRIPTION

Steel grid element resistors (Type EPH-S) are made of heat-resistant steel. The resistance value of the individual elements are temperature-dependent and the temperaturecoefficient is higher than classic wire-wound power resistors, Type ALW, however much smaller than the cast resistors. The design of these power resistors is a derivative of the Türk+Hillinger plate heater, Type EPH, which is designed with heating capacities of up to one (1) megawatt for applications that require high electrical performance and ruggedness.

In addition to the classic application as a heating or chopper resistance, the design can also be used for the following resistances: current limiting, discharge, as crowbar, FRT, LVRT, emergency stop, load, starting, permanent, braking or filter resistance.

The energy absorption capacity of the Type EPH-S, available from inventory, is between 50 and 70 kJ (= kWs) at a temperature increase of 300°K at dormant air. The average thermal time constant is 100 seconds. By varying different individual steel grid resistance elements, it provides and covers a wide range of benefits, energy absorption and ohm values.

OPTIONS

- Housings of different types of protection

- Fan

- Temperature switch

- Thermal overcurrent switch

- Connection elements

Türk+Hillinger Elektrowarme GmbH

09212 Limbach-Oberfrohna,

Deutschland

Railway point heater Type RKW

DESCRIPTION

Complete, ready to use heating units for rail points, consisting of flat heater type RKF-24 and watertight connection box. All accessories for fixing to standard S 49, S 54 and UIC 60 rails.

TECHNICAL DATA

| Operating voltages | up to 800 V |

APPLICATION

For heating points on railways and tramways.

Contact Persons

Carmen Jurj

Order Processing

PMVA – Compacted heating cartridges

RKW – Electric railway switch heaters

RP – High performance tubular heaters

SCHUWI – Protective resistors

TE – Temperature sensors

Immersion Heater Type EHK

DESCRIPTION

Electrical heating element consisting of 3 u-shaped tubular heaters, which are brazed or welded onto a threaded nipple G 11/2 and can be supplied with a thermostat or / and a temperature limiter.

TECHNICAL DATA

| Surface loading | Depending on the medium to be heated up to 25 W/cm² |

| Temperature resistance | up to max. 850°C |

| Max. immersion depth | 2200 mm |

| The immersion heaters are equipped for the use with 3-phase connection 400 V or with parallel connection 230 V |

APPLICATION

Heating of liquid and gaseous media e. g. provision of hot water, boilers, oil heaters, air heaters.

Contact Persons

Ralf Kuppel

Technical Sales

FLC – Flat heating elements

ALW – Power resistor

RKF – Flat tubular heaters

Diane Fiedler

Order Processing

EHK – Immersion heaters

FLC – Flat heating elements

RKF – Flat tubular heaters

FLEX – Flexible tubular heater

Flanged heater Type FH

DESCRIPTION

Flanged heating elements with and low surface loads high performance.

TECHNICAL DATA

|

Possible voltages |

up to 700 V |

APPLICATION

For heating oil, water, drinking water, air, CO2 and another gaseous. Process heat for several applications, building technologys, renewable energy. Heating of buffer storage tanks and steam generators. Antifreeze and many other application possibilities: contact us to find if your application is not here be referred to an appropriate solution.

Türk+Hillinger Elektrowarme GmbH

09212 Limbach-Oberfrohna,

Deutschland

Finned tubular heating element Type RHR

DESCRIPTION

Finnend tubular heating elements are based on a RHK type heaters. The surface area is enlarged by a strip in order to heat gases. At a high power the surface temperature is small and the heating element is short.

TECHNICAL DATA

| max. temperature at tube sheath | 700° (at CrNi-steel) |

| diameters (with RHK 8,5mm) | 20 and 28 mm |

| Distance between fins | 5 mm |

APPLICATION

Channel air heaters for air-conditioning and drying apparatus

Türk+Hillinger Elektrowarme GmbH

09212 Limbach-Oberfrohna,

Deutschland

Electrical air heater Type HRR

DESCRIPTION

Channel heater with a housing of zinc-plated sheet metal with flanges on both side and mounted finned heaters type RHR.

TECHNICAL DATA

| Wattages | from 2 to 108 kW |

| Dimensions | from 250x250x108mm to 800x800x250 mm |

APPLICATION

Air conditioning and climatisation, industrial dryers

Türk+Hillinger Elektrowarme GmbH

09212 Limbach-Oberfrohna,

Deutschland

Spiral heater Type HR

DESCRIPTION

Heater with exosed heating filament located onto ceramic former or mica strip with a sheet metal housing. For use only with upstream or downstream fan blowers.

TECHNICAL DATA

| Operating voltages | up to 440 V |

| Max. loading | approx. 9 W/cm² |

| Max. temperature | approx. 600°C |

| Standard version | up to 3000 W |

| Outer dimensions | 360x50x90 mm, 160x54x100 mm, 235x50x85 mm |

APPLICATION

For tumbler dryers and industrial hot-air blowers.

Türk+Hillinger Elektrowarme GmbH

09212 Limbach-Oberfrohna,

Deutschland

Flat heating element Type FLC

DESCRIPTION

Flat heating element with CrNi-steel sheath and integrated tubular heater type RHK.

TECHNICAL DATA

| Voltage | up to 480 V |

| Surface loading | abt. 7 W/cm² |

| Dielectric strength | abt. 1,25 kV |

| Temperature resistance | abt. 750° C max. |

| Section | 33 x 7 mm |

| Length | 200 - 600 mm |

| Connections | threaded tab M4 |

APPLICATION

Heating of surfaces, e.g. heating boilers, heating frames, heating of plates, stamping dies and moulds, antifreeze for liquid tanks.

Contact Persons

Ralf Kuppel

Technical Sales

FLC – Flat heating elements

ALW – Power resistor

RKF – Flat tubular heaters

Diane Fiedler

Order Processing

EHK – Immersion heaters

FLC – Flat heating elements

RKF – Flat tubular heaters

FLEX – Flexible tubular heater

PTC-heating element Type HLPR

DESCRIPTION

Heating elements in cartridge shape or in special executions equipped with self-regulating resistance elements.

TECHNICAL DATA

| Diameter | 9mm, 10mm, 11mm, 12mm, 16mm |

| Length | 50 mm to 1400 mm (Ø 12 mm) |

| Power | max. 400 W |

APPLICATION

Heating of liquids, preheating of oil and petrol, frost protection.

Contact Persons

Jürgen Wiggenhauser

Technical Sales

HP – Nozzle heaters

HLP – High performance cartridge heaters

HLPR – PTC-heating elements

Fax: +49 (0) 74 61-70 14 - 148

Email: wiggenhauser@tuerk-hillinger.de

Heating unit without metal casing Type PK

DESCRIPTION

Ceramic unit without metal casing. The heating wire is located in several axially-parallel holes and is prevented from coming out by locked ends. The connections are on a plug-in head.

TECHNICAL DATA

| Voltages | up to 440 V |

| Surface loading | 22 W/cm² |

| Max. temperature (sheath) | 650° |

| Diameter | 26; 32 and 45,9 mm |

| Connections | Plug twins or twisted ends |

APPLICATION

For heating gaseous media, e.g. for welding plastic.

Türk+Hillinger Elektrowarme GmbH

09212 Limbach-Oberfrohna,

Deutschland

Heating Series PK – 150 x 150 up to 1000°C

Description

The world's first reliably functioning air heating element up to 1000 °C in the form factor 150 x 150 mm based on resistance elements. The application is not limited to pure air heating, but is successfully used in special plant construction in the areas of exhaust gas treatment and the heating of industrial gases.

Due to the standardized form factor, production is possible from a quantity of 1. For air volumes of 50–1000 m³/h, outputs of up to 50 kW per element are available in all voltage levels and circuits, depending on the application. Larger volume flow rates and outputs are possible by combining several heating elements.

Options

Important notes

- Air volumes or air speeds

- Desired inlet and outlet temperatures or the maximum temperature to be

- reached for recirculation applications.

- Special requirements of the application, e.g. corrosive components in the air flow, LABS-free, odor prevention, e.g. for ventilation systems in buildings, ...

Türk+Hillinger Elektrowarme GmbH

09212 Limbach-Oberfrohna,

Deutschland

Compacted heating element Type PMVA

DESCRIPTION

Heating element with CrNi-steel sheath. Insulated by compacted MgO. Insulated connection leads at one end and steamproof seals.

TECHNICAL DATA

| Operating voltages | 10 to 250 V |

| Surface loading | approx. 10 W/cm² |

| Max. temperature | approx. 600°C |

| Diameter | 9,6 ± 0,1 mm |

| Min. length | 165 mm of which 80 mm is heated. |

| Power | 65 to 250 W |

| Connections | copper leads with double insulation if requested |

APPLICATION

Absorption type refrigerators, oil preheaters

Contact Persons

Carmen Jurj

Order Processing

PMVA – Compacted heating cartridges

RKW – Electric railway switch heaters

RP – Cartridge heaters

SCHUWI – Protective resistors

TE – Temperature sensors

Lightly compacted cartridge heater Type PMV

DESCRIPTION

Metal-sheathed catridge heater with outer sheath of CrNi-steel. Compared with conventional catridge heaters of the same dimension and power, these have greater mechanical strength and a longer life. Suitable for heating solid and fluid media.

TECHNICAL DATA

| Diameters | 10; 12,5; 16; 20 mm |

| Surface loading | abt. 6,5 W/cm² |

| Permissible temperature rise | 750° C |

| Tolerance on diameter | +0,2mm |

| Connections | pure nickel wire 30mm or insulated leads |

| Voltage | 230 V |

APPLICATION

Plastics industry, engineering industry, wood working machinery, shoe-making machinery, domestic appliances, high-vaccum techniques, foundries, laboratory work, packaging industry

Contact Persons

Lucas Denger

Order Processing

HLP – High performance cartridge heaters

PMV – Compacted heating element

Emily Hermes

Order Processing

HLP – High performance cartridge heaters

PMV – Compacted heating element

_