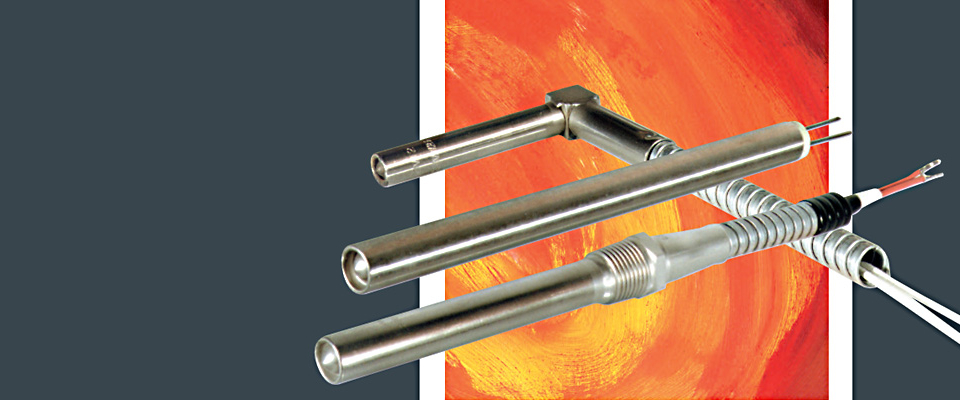

PMVA – Compacted heating element

7. September 2017

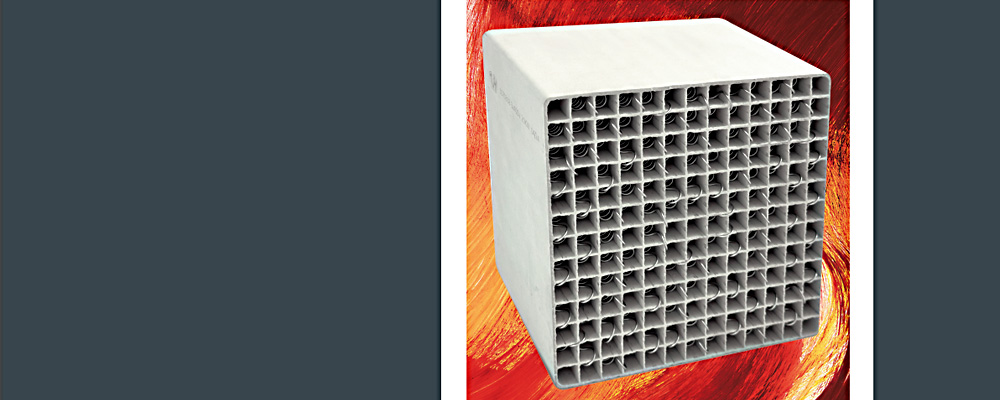

PK – Heating unit without metal casing

7. September 2017Heating Series PK – 150 x 150 up to 1000°C

Description

The world’s first reliably functioning air heating element up to 1000 °C in the form factor 150 x 150 mm based on resistance elements. The application is not limited to pure air heating, but is successfully used in special plant construction in the areas of exhaust gas treatment and the heating of industrial gases.

Due to the standardized form factor, production is possible from a quantity of 1. For air volumes of 50–1000 m³/h, outputs of up to 50 kW per element are available in all voltage levels and circuits, depending on the application. Larger volume flow rates and outputs are possible by combining several heating elements.

Options

Important notes

- Air volumes or air speeds

- Desired inlet and outlet temperatures or the maximum temperature to be

- reached for recirculation applications.

- Special requirements of the application, e.g. corrosive components in the air flow, LABS-free, odor prevention, e.g. for ventilation systems in buildings, …

Türk+Hillinger Elektrowarme GmbH

09212 Limbach-Oberfrohna,

Deutschland