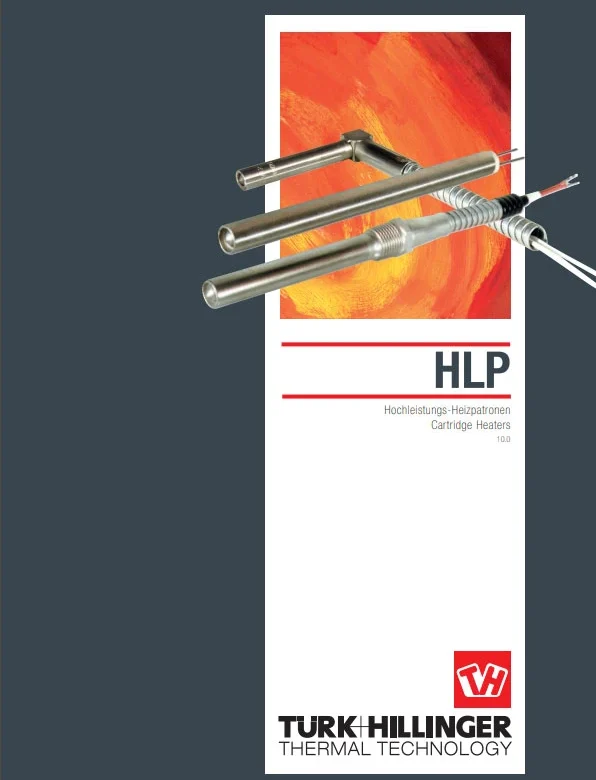

DESCRIPTION

Metal-sheathed cartridge heater with ground sheath. The special construction allows an extremely high surface loading, i.e. maximum power in the smallest possible space. UL-approved executions available

TECHNICAL DATA

| Technical Data | Details |

|---|---|

| Possible voltages | to 1000 V |

| Surface loading | approx 3–50 W/cm² |

| Temperature | approx 750°C max. |

| Operating diameter (mm) | up to 2.8 mm – 32 mm |

| Operating diameter (inch) | from 1/8 |

| Connections | Solid wire or flexible leads. Custom-made lengths. |

APPLICATION

Plastics industry, apparatus construction, woodworking industry, paper machine industry, medical technology, foundries, high vacuum technology, laboratory work, packaging industry. The heating cartridge is used to heat tools, components, and media in various applications. It is designed for reliable heating and can be operated in conjunction with a controller or temperature controller to ensure precise and constant temperature control.

Contact Persons

Technical Sales

HLP – High performance cartridge heaters

HLPR – PTC-heating element

Fax: +49 (0) 74 61-70 14 – 148

E-Mail: wiggenhauser@tuerk-hillinger.de

Order Processing

PMV – Compacted heating element

Order Processing

PMV – Compacted heating element

Order Processing

Order Processing

FAQ - Frequently Asked Questions

How is the appropriate high-performance heating cartridge selected?

The selection depends on the power requirement, temperature requirements, and available installation space. Other decisive factors include surface load, component material, and the type of temperature control. Precise coordination of these parameters ensures efficiency and a long service life for the heating cartridge.

What are the typical causes of heating element failure?

Common causes include overheating due to insufficient heat dissipation or faulty temperature control. Mechanical damage during installation, material fatigue due to temperature fluctuations, and corrosion due to contact with aggressive media are also common causes.

Why is energy efficiency important for heating cartridges?

Energy efficiency reduces operating costs and supports compliance with environmental regulations. Modern heating cartridges achieve high heat transfer through optimized materials and designs. Precise control systems adjust the heating output according to demand, thereby reducing energy consumption.

How do compacted heating rods differ from conventional heating elements?

Compacted heating rods have a high surface load, which enables high power ratings in the smallest of spaces. This results in short heating times that cannot usually be achieved with standard heating elements.

What technological innovations characterize current high-performance heating cartridges?

Modern high-performance heating cartridges are characterized by higher power densities and improved temperature resistance thanks to new alloys. Integrated temperature sensors increase control precision, while optimized manufacturing processes increase service life and reliability.

How does heat dissipation affect the service life of heating elements?

Insufficient heat dissipation causes overheating and shortens the service life of heating elements. With optimal dissipation, heat is efficiently transferred to the medium, the internal temperature remains within the permissible range, and material fatigue is reduced.

What requirements apply to the installation of heating cartridges?

It is crucial to ensure a precise fit with minimal clearance between the cartridge and the holder in order to guarantee efficient heat transfer. Good thermal coupling prevents cavities and thus overheating. In addition, correct electrical wiring and adequate insulation are essential for safety and performance.

Deutsch

Deutsch  Chinese

Chinese  English

English